Higher productivity. Lower operating cost.

ARO Welding Technologies has launched its revolutionary manual welding station incorporating cutting-edge Servo technology.

Servoline takes manual welding to performance levels that were previously only possible with robotic applications, while protecting the environment at the same time by eliminating compressed air.

Servoline is a turnkey concept that incorporates the most recent ARO innovations for unparalleled weld quality. Workstation ergonomics have also been optimized to improve and facilitate the work of operators.

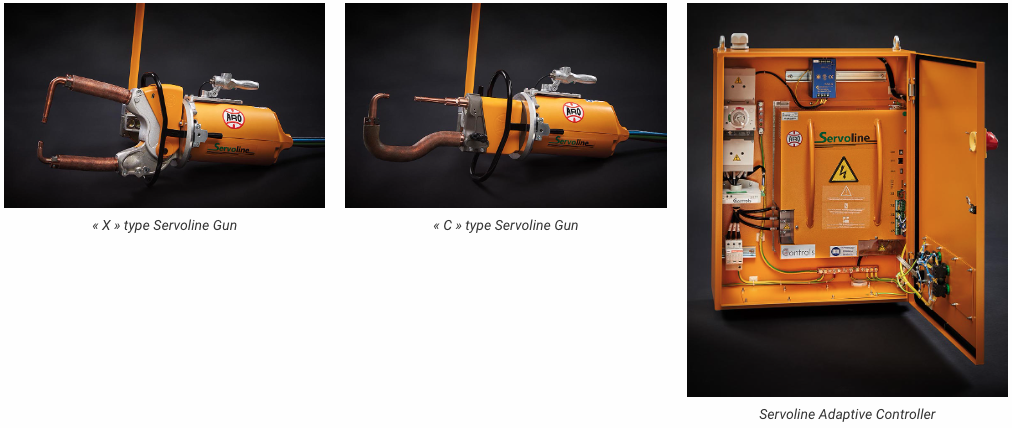

To cater for all requirements, the Servoline range comprises several models of extremely compact weld guns controlled by a new dedicated adaptive controller. The gun body is fully enclosed with reinforced suspension components to make the welding application safer. Delivered ready to use, the station is up and running in less than 15 minutes!

With these advantages, Servoline opens the door to new perspectives in manual welding to tackle the technical and economic challenges of the marketplace. This new concept is the culmination of years of R&D and the result of major investments in design and tooling.

For further information please contact us at (info@arotechnologies.com or +33 (0)2 43 44 74 00).

About ARO

ARO is a widely recognized world leader in resistance welding, notably to the automotive industry. The ARO group is headquartered near Le Mans in France, with subsidiaries in Germany, Spain, Belgium, Slovakia, Sweden, the UK, USA, Mexico, Brazil and China. The company was founded in 1949 and today employs around 500 persons. ARO is a member of the British engineering and industrial group Langley Holdings plc.

| Servoline Manual Welding Station | 1.33 MB | Download |