MFDC Controllers

MFDC Controllers

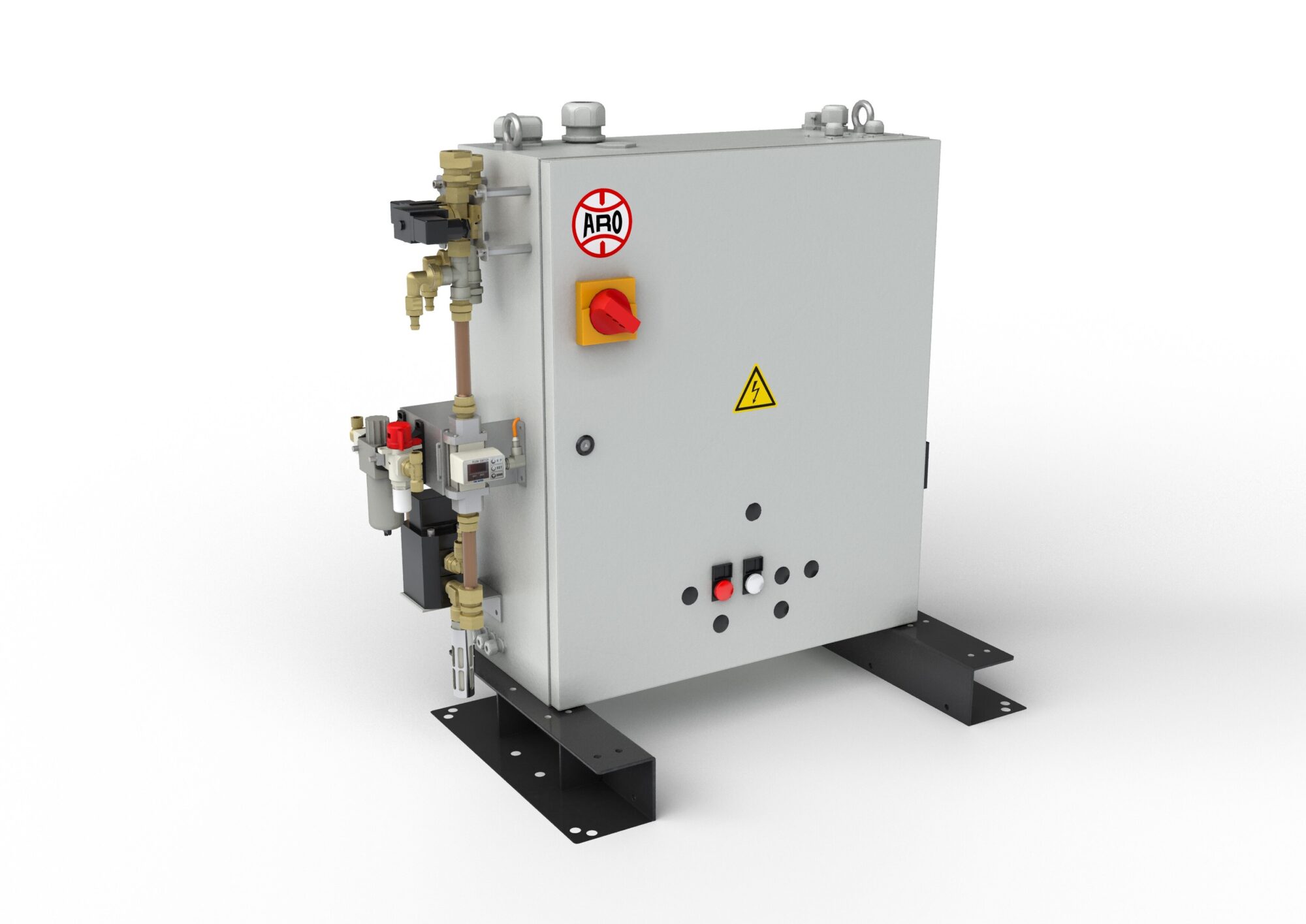

ARO provides a standard range of MFDC welding cabinets covering manual, robot and stationary machine applications.

They integrate a complete and coherent range of inverters (also available as components) with embedded controllers compatible with a large majority of field buses such as Ethernet IP, Profinet IO, DeviceNet, Interbus-S, Profibus DP.

- Ability to manage up to 256 welding schedules

- Wide choice of options

- Compact design

- Worker safety

- Maximum flexibility

- Adaptive Welding and Quality Assurance

Adaptive Welding

Self LEARNING

Possibility to copy the Learning (reference) from a gun to any other

Adaptive mode will compensate :

▪ Different materials and thicknesses (for manual welding)

▪ Tips wear

▪ Presence of adhesive

▪ Poor part fit

▪ Shunting effects

▪ Shunting effects

Adaptive Welding

Intelligent and efficient, Adaptive Welding automatically compensates process variations to guarantee superior weld quality.

SQA (Steel Quality Assurance)

- Steel Quality Assurance function (SQA) assigns a % to each spot to grade the quality of the welding

- Dedicated to robotized applications, the principle is also based on dynamic resistance during the weld formation

- It povides with weld quality and process deviations

Features

- Three phases balanced current : Lower electrical consumption ( Over 20% saving)

- Welding current is not disturbed by main network voltage variations

- Better welding quality/Lower welding current/Spattering reduced

- Lightweight equipment

- Improved weld quality

- Reduction in time and associated cost savings for equipment start-up

- Reduction of expulsions which minimizes maintenance costs

- Reduced off-line quality control expenses

- Easier welding of complex materials (HSS, AHSS, PHS -boron, etc.)

- Evaluates weld quality Detects process disturbances (mechanical and electrical

failures, shunt effect, different coatings, adhesive, electrodes sliding etc…) - SQA can be used either in standard or adaptive welding mode

- Automatic reweld function based on SQA%

- Threshold of the SQA% is set by the weld engineer

MFDC Cabinets

- Process: Robotic

- Output current: 560A

- Field bus: Yes

- Adaptive Welding: Option

- SQA: Option

- Process: Manual

- Output current: 560A

- Field bus: No

- Adaptive Welding: Option

- SQA: Option

- Process: Machines

- Output current: 560A

- Field bus: Option

- Adaptive Welding: No

- SQA: No

- Process: Robotic

- Output current: 800A

- Field bus: Yes

- Adaptive Welding: Option

- SQA: Option

- Process: Manual

- Output current: 800A

- Field bus: No

- Adaptive Welding: Option

- SQA: Option

- Process: Machines

- Output current: 800A

- Field bus: Option

- Adaptive Welding: No

- SQA: No

- Process: Robotic

- Output current: 1200A

- Field bus: Yes

- Adaptive Welding: Option

- SQA: Option

- Process: Manual

- Output current: 1200A

- Field bus: No

- Adaptive Welding: Option

- SQA: Option

- Process: Machines

- Output current: 1200A

- Field bus: Option

- Adaptive Welding: No

- SQA: No

- Process: Robotic

- Output current: 2400A

- Field bus: Yes

- Adaptive Welding: Option

- SQA: Option

- Process: Machines

- Output current: 2400A

- Field bus: Option

- Adaptive Welding: No

- SQA: No