Parent Company Interim Report Released Today

Read More

Supporting Manufacturing Success with Reliable Welding

Read More

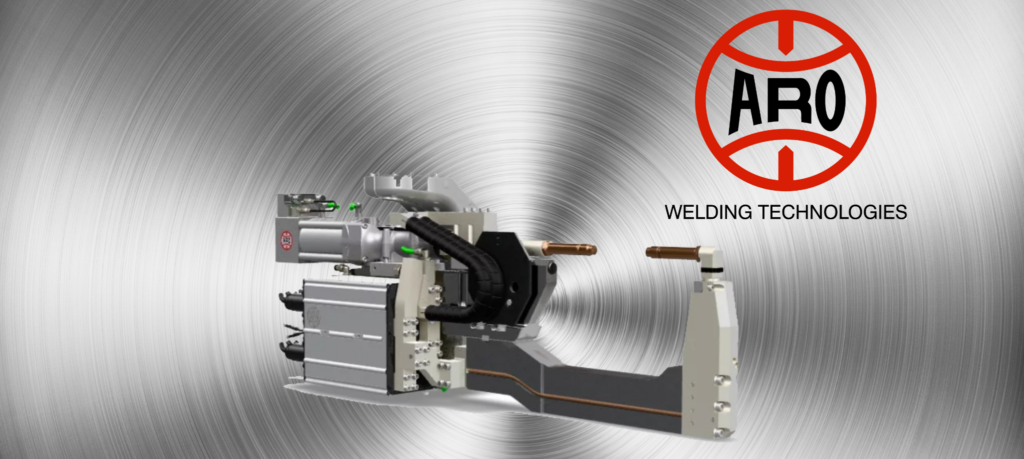

ARO Introduces the H-Series Aluminium Welding Guns

Read More

2024 Results Published

Read More

ARO Celebrates 75 Years of Excellence

Read More

ARO accelerates in Sweden and Norway

Read More