About

ARO Welding Technologies - Leader in Resistance Welding

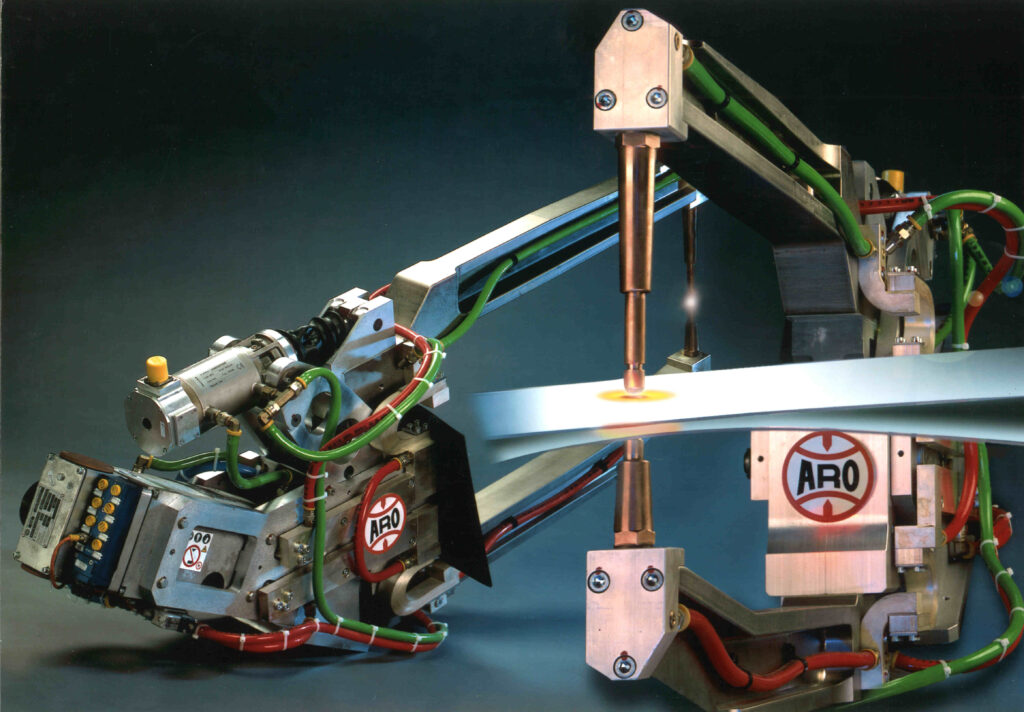

Since 1949, ARO Welding Technologies SAS has been a leader in resistance welding technology providing the automotive and manufacturing industries with innovative robotic welding, manual welding and stationary welding systems. From spot welding and projection welding, to seam or butt welding, we provide the optimum solution. ARO is headquartered in Chateau-du-Loir, near Le Mans in France, with regional offices in Europe, the Americas and the Far East as well as independent sales and services partners. ARO is a division of the multi-disciplined UK engineering group, Langley Holdings plc.

Our history

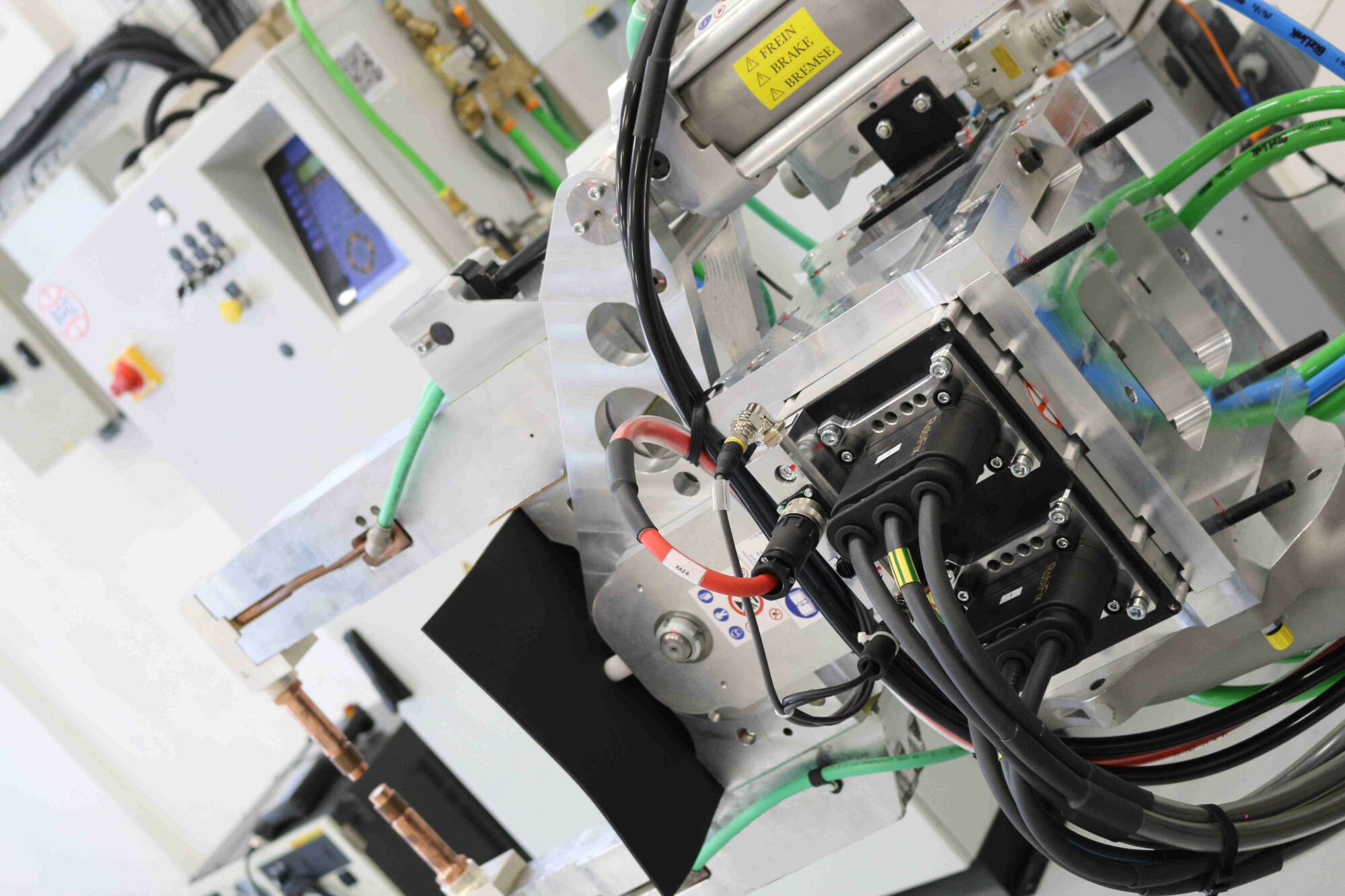

ARO innovates by proposing SERVO manual solutions

Immediate savings and simplicity: the use of the servo technology eliminates the need for compressed air in manual welding.

Servoline: servo manual welding station. The Servo technology brings to the manual welding operations all its strong benefits – high performances, cost efficiency, and highest reliability. – henceforth recognized by the automotive industry using almost 100% of sevo welding guns for robotics.

Resistance Spot Welding of Aluminium Alloys: Full Solution Package

Resistance spot welding is the dominant joining technology in vehicle construction as it offers a number of advantages: high speed, low cost, limited fixturing, high flexibility and high process robustness. Motivated by light weighting, more aluminium alloy parts have been introduced in the BIW and several major OEMs already successfully apply RSW to join those parts in aluminium intensive vehicles mass production.

Documents

-

ARO Profile

-

ARO Certificate ISO 14001

-

ARO Certificate ISO 9001

-

ARO Quality and Environmental Policy