Our Products

Our Products

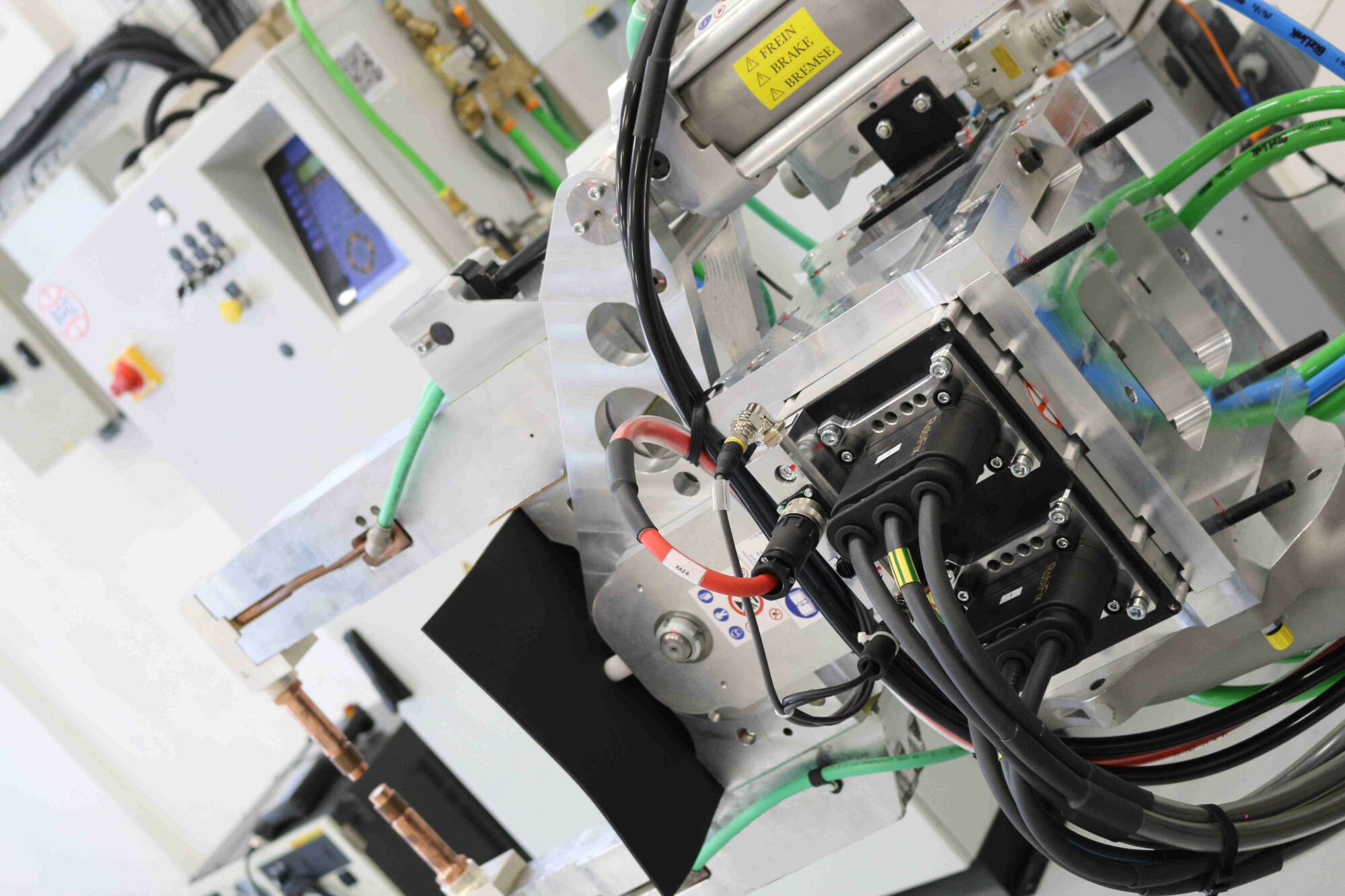

Robotic Weld Guns

Integrated transformer weld guns have revolutionised robotic assembly lines; tens of thousands of ARO robotic weld guns have equipped the large automotive manufacturing plants for many decades.

Manual Weld Guns

ARO innovates by proposing SERVO manual solutions. The Servo technology brings to the manual welding operations all its strong benefits - high performance, cost efficiency, and highest reliability - henceforth recognized by the automotive industry using almost 100% of Servo weld guns for robotics.

Stationary Weld Machines

ARO provides a large range of solutions to meet all the needs of spot, seam, butt and projection welding applications. Manufactured from standard modules, these machines are assembled in minimum time for perfect cost control.

Mobile Welders

The ARO mobile welding product range was developed with the automotive motor body repair (MBR) market firmly in mind. Today, ARO continues to innovate, providing solutions for higher production through the provision of the multi-function equipment and lower operating costs demanded by today’s automotive repair market.

Controls & Software

ARO offers a large range of integrated welding controllers equipped with the latest technology of welding controls. From the standard AC-MFDC cabinets to the advanced concept cabinets (auto-adaptive).

Welding Components

ARO designs and manufactures its own range of transformers, Servo motors and electronic controls because they are essential components of the resistance welding process.

Welding Peripherals

A large range of accessories and peripherals, reliable and high performance, they become the elements that you cannot do without when implementing global welding solutions.

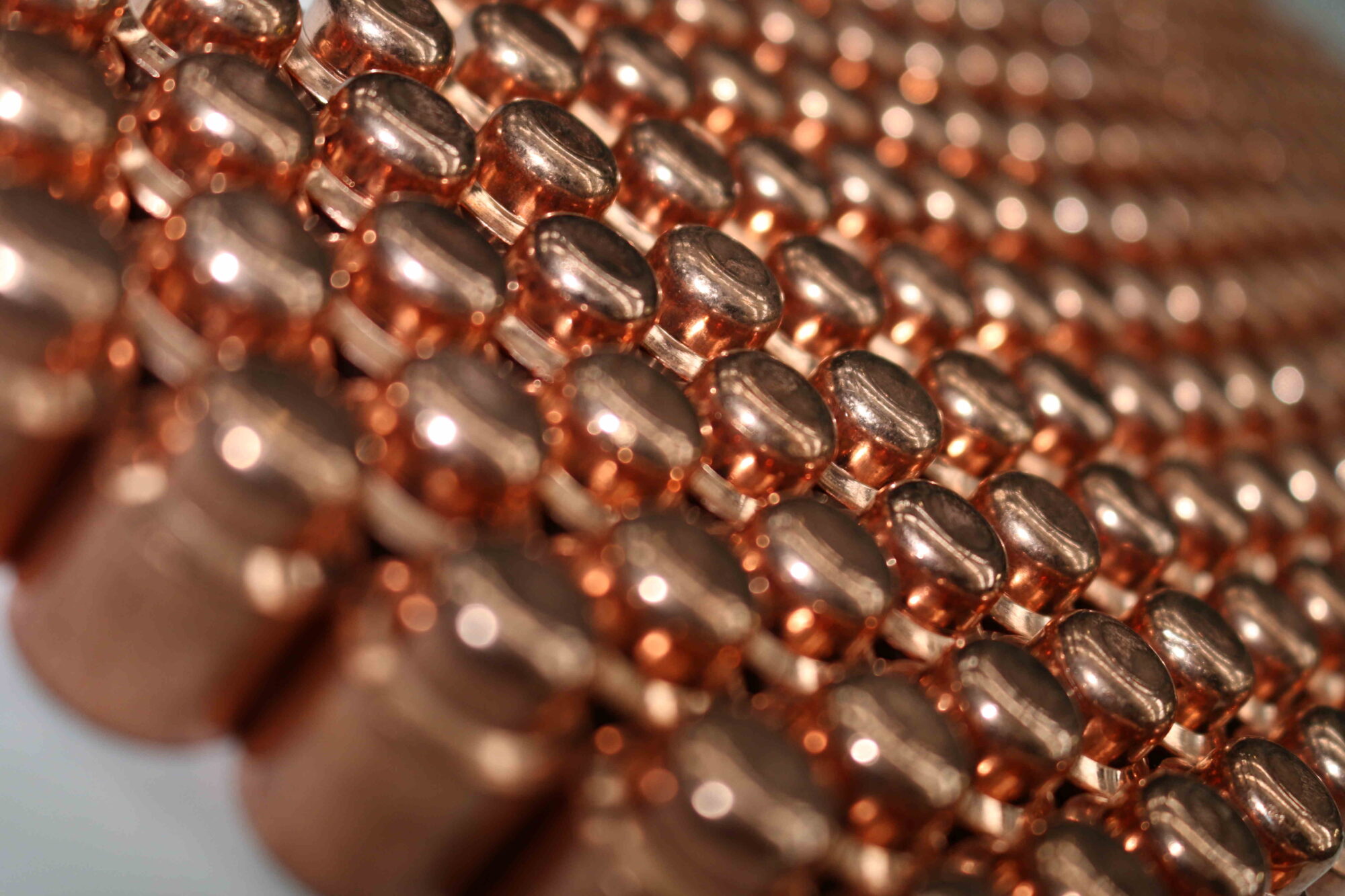

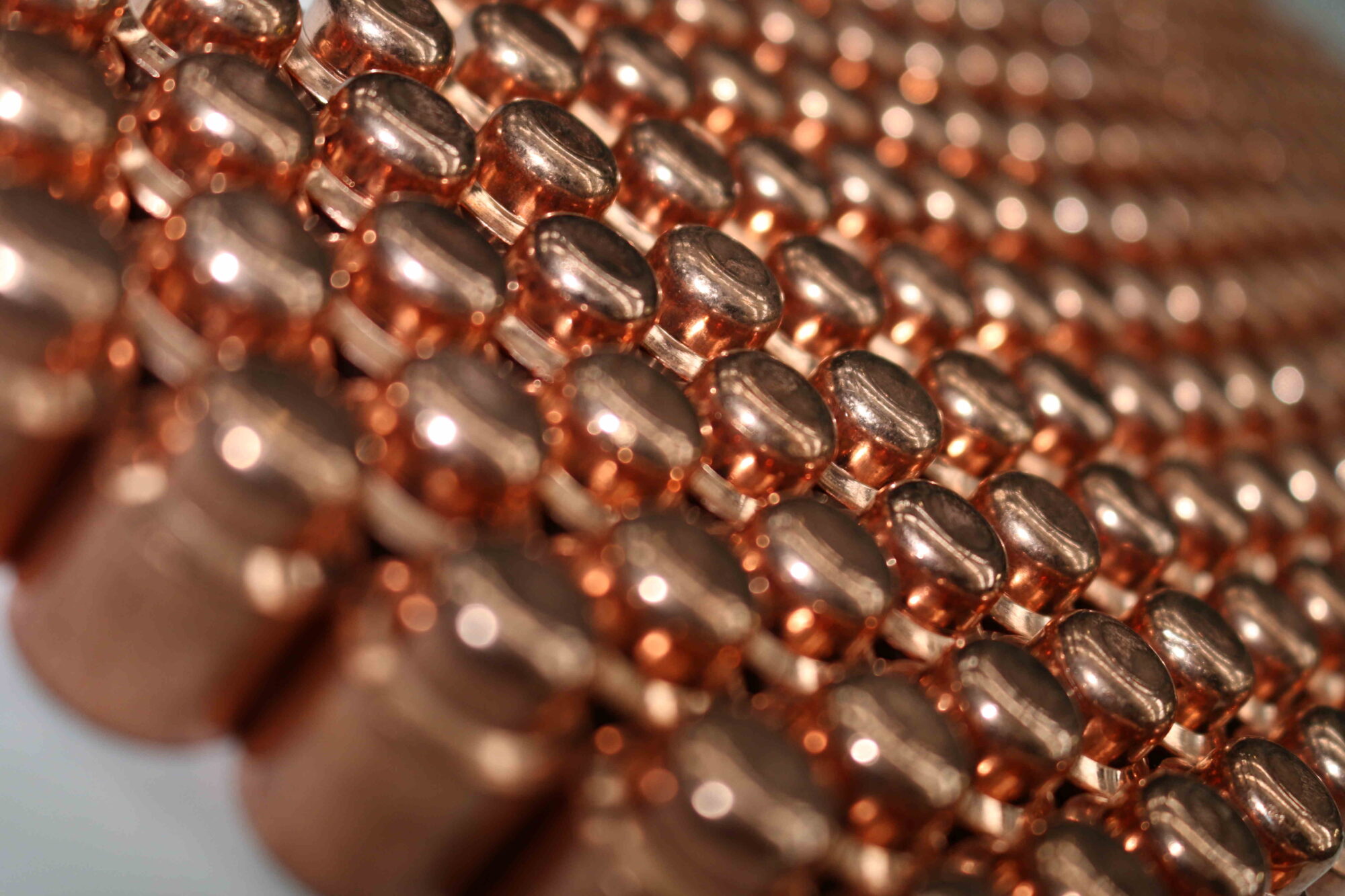

Welding Consumables

ARO offers a diverse range of electrodes for all welding applications. Different shapes and materials to perform high quality welds even under most severe conditions. ARO also offers a wide range of straight and bent cap adaptors, designs and manufactures specific parts upon request.